There was a time when most electronics devices were installed and left to sit. That’s changed dramatically over the last decade with wireless connectivity, mobile carried devices and electronified cars. Modularity is also a significant factor in modern electronics and with modularity comes PC board connectors.

There was a time, log ago, when most connections were soldered, but that’s no longer practical. Modular design and manufacturability concerns mean that functional blocks are often distributed. Even fixed electronics in stationary machinery often need cabling between PC boards and that configuration must consider vibration induced reliability issues. Unsecured connectors can work their way loose. Bolts can back off. wires can brush against stuff. A lot of practices that don’t cause problems in a stationary, non vibration-likely fixed installation can bite in a mobile or vibration-likely setting.

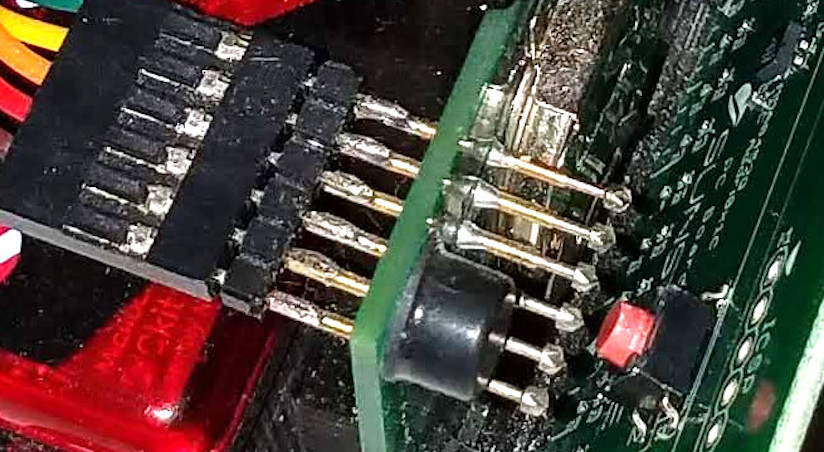

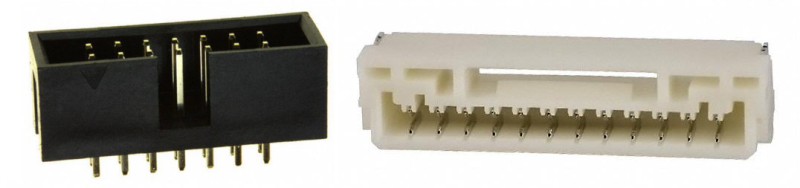

For example; take a simple board to board ribbon cable. On the left, is a common friction-retention cable receptacle for an IDC (Insulation-displacement connector) connector. Ignoring the fact that calling something an IDC connector is 1/3 redundant, friction connectors are fine for a development board, but not for an environment subject to vibration. Instead, use a mechanically captive connector, as shown on the right.

Free hanging cables are also a “no” for mobile devices. Cables hanging loose can get caught on edges, or tall or hot components. That can lead to worn or melted insulation and shorts. Instead, use cable ties, insulating grommets, and careful routing.

There are plenty of other considerations, but these are two of the biggest traps to avoid when movement is called for.

Duane Benson

Klaatu barada nikto. Translation: “Spaceman says what”

And don’t hesitate to move those connectors and other parts (or just the design files so we can buy everything) to Screaming Circuits. Visit our PCB assembly quote page and get a PCB assembly quote.